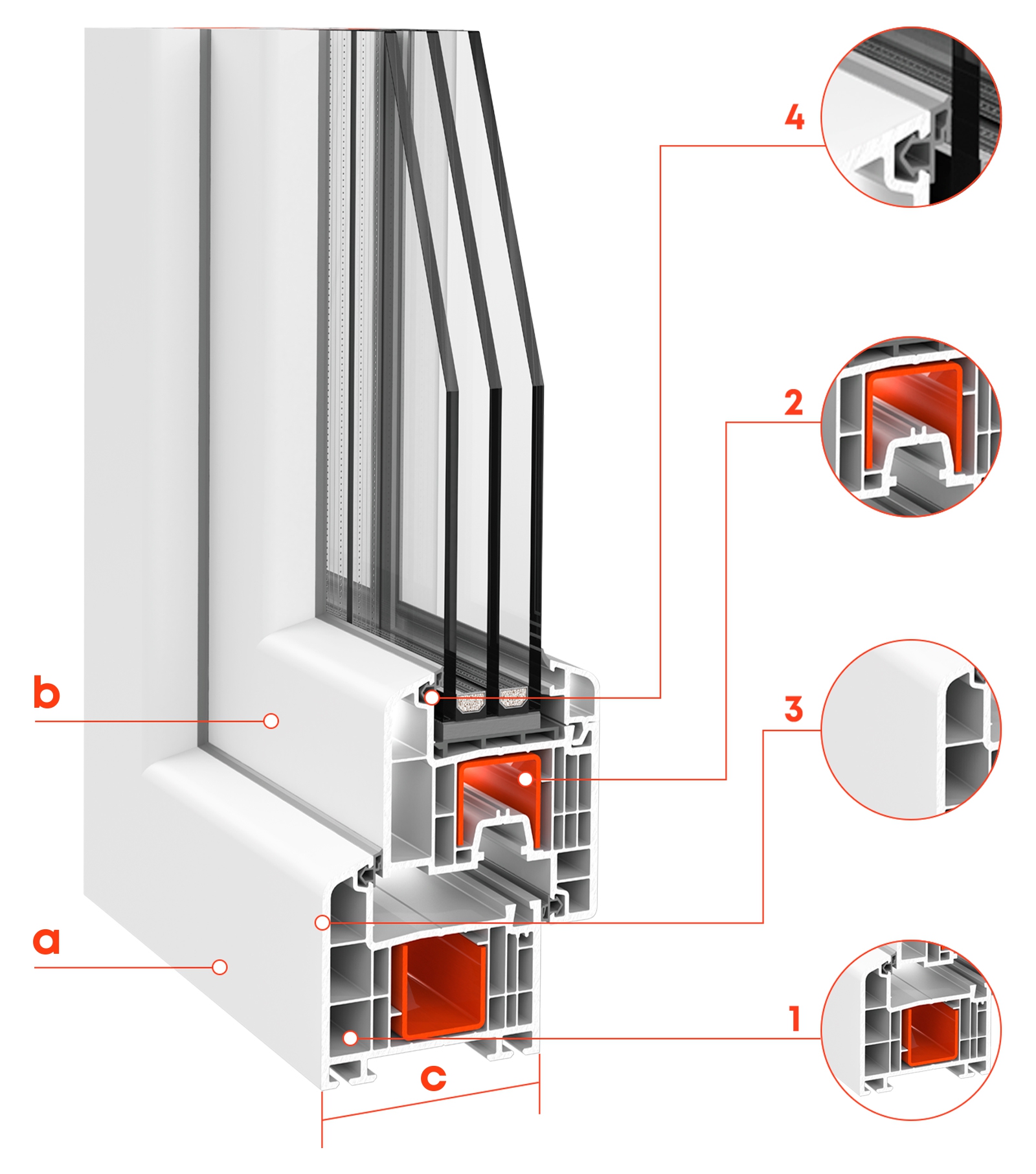

- Number of chambers - 7

- Installation depth - 80 mm

- Seal - triple contour, TPE

- Filling thickness - 42 mm, 50 mm

- The profile heat transfer coefficient - 1,1 W/m².K

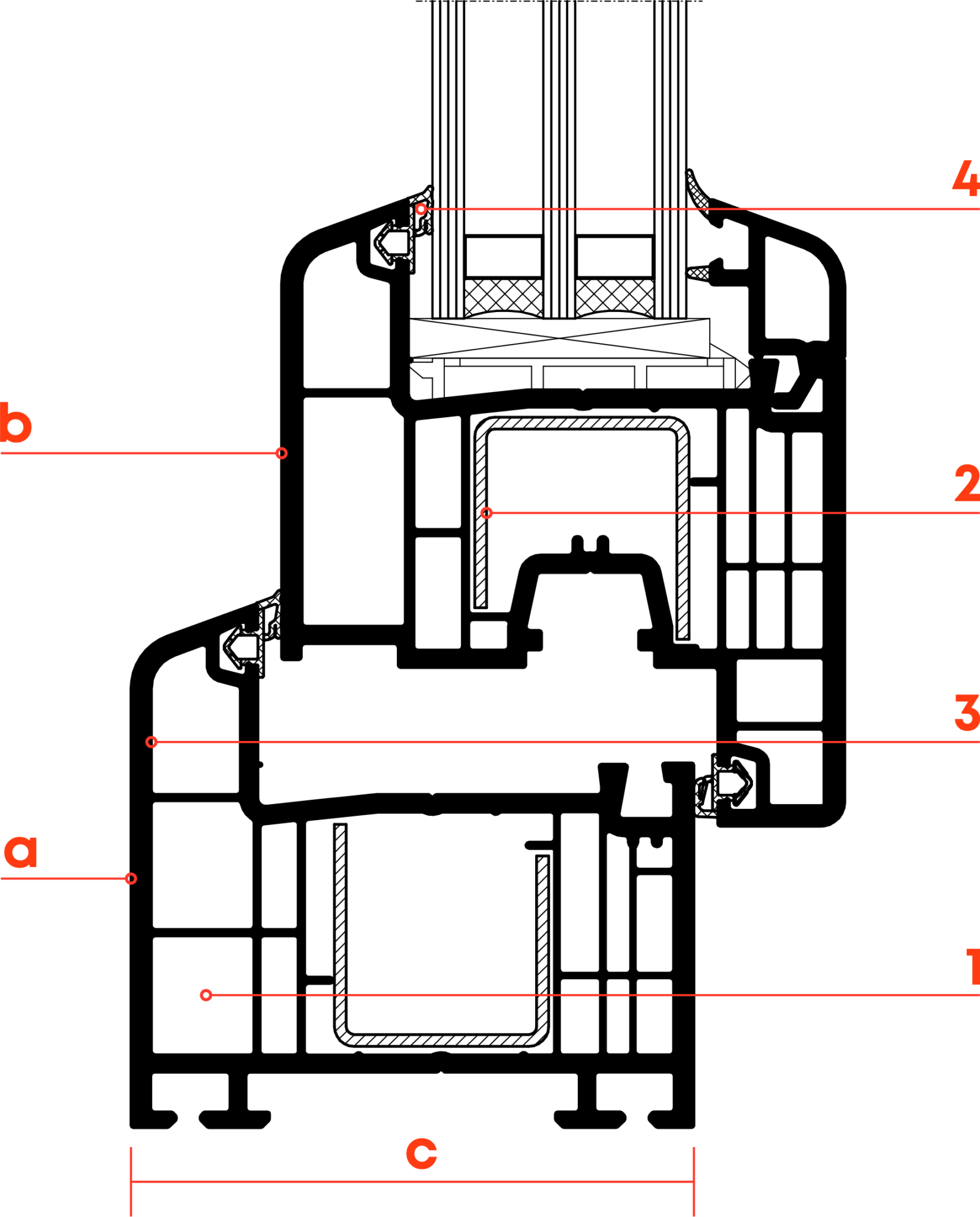

- Number of chambers - 6

- Installation depth - 71 mm

- Seal - double contour, TPE

- Filling thickness - 24 mm, 32 mm, 42 mm

- The profile heat transfer coefficient - 1,2 W/m².K

- Number of chambers - 4

- Installation depth - 58 mm

- Seal - double contour, TPE

- Filling thickness - 4 mm, 24 mm, 32 mm

- The profile heat transfer coefficient - 1,47 W/m².K