Do you have any further questions?

Our specialist will contact you shortly and answer all questions regarding Framex.

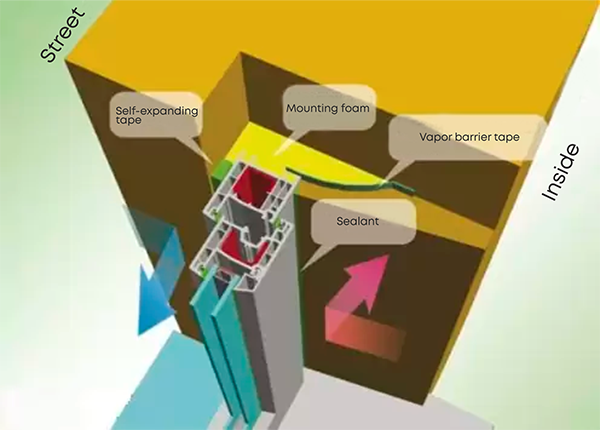

Installation according to DSTU is a state-developed and rigorously tested mandatory window installation technology It involves creating a special protected installation joint between the window frame and the wall.

This installation joint is designed for many years of operation (20 years) The principle of creating the installation joint is very simple: protect the insulator (Expert installation foam) inside the window joint from adverse effects both from outside and inside the premises.

Among such influences, two main ones can be highlighted – ultraviolet (sun rays) and moisture (water and steam).

The technology laid down in the DSTU is aimed at protecting the installation seam for a term of at least 20 years, which is much longer than the standard warranty period. Moreover, manufacturers of modern plastic windows speak of a lifespan of these structures up to 50 years. How long can the service life of individual materials of the installation seam be?

For example, the lifespan of installation foam that is not protected from the influence of UV radiation (both direct and reflected sunlight) ranges from 3 to 6 months. With excessive moisture and constant temperature fluctuations from minus to plus, the installation foam can degrade within just a few months, during which mold and fungus may also develop.

The solution to this issue would be a complete or partial reinstallation, which is costly. Therefore, to ensure the lifespan of the window assembly and the installation joint are equivalent, we recommend not taking risks and using the DSTU installation technology with Expert materials.

It’s important to inform the client that these negative processes do not occur universally Their occurrence depends on many factors:

Installation using the technology described in DSTU, with protected installation foam and creating a mounting seam based on the principle of tighter inside than outside, is more complex.

Installers face a whole layer of additional work, starting from the need, in some cases, to prepare the window opening, to applying protective materials on the external and internal contours of the window.

Additionally, the cost of the materials themselves, which are not used in the cheap version, is taken into account.

Additionally, the following materials are used:

On the outside – a pre-compressed self-expanding sealing tape (PSUL Expert tape), as well as an external waterproofing tape Expert – for protecting the lower part of the window seam (under the sill) or for protecting the external seam in the case of installing a window in an opening without a rebate.

On the inside, the internal vapor barrier tape Expert is used, which prevents moisture penetration (forming in the plane of the wall), both from the room into the window seam and vice versa: from the window seam into the room.

For an aesthetic and finished exterior appearance of the window, as well as additional insulation, Expert materials are used for finishing the slopes: both external (Expert sandwich panel) and internal (extruded cellular G-shaped PVC profile Expert).

Our specialist will contact you shortly and answer all questions regarding Framex.

Please enter your username or email address. You will receive a link to create a new password via email.